Nic Thomassen has more than 40 different types of masks piled up in his Seattle office – from minimalist rectangles with fabric ear loops to more complicated configurations with filter pockets, adjustable straps, metal nose wires and other features. He knows which ones fit the most comfortably, which offer superior breathability, which keep your glasses from fogging up and which can most easily be customized because he’s tested them all.

NEARLY TWO-THIRDS

of consumers (63%) wear masks all the time when in public.

2020 ASI Global Ad Impressions Study

“Everything’s been on the fast-track here,” says the creative director and co-founder of Top 40 distributor Kotis Design (asi/244898). “This has been a fast-forward on Masks 101.”

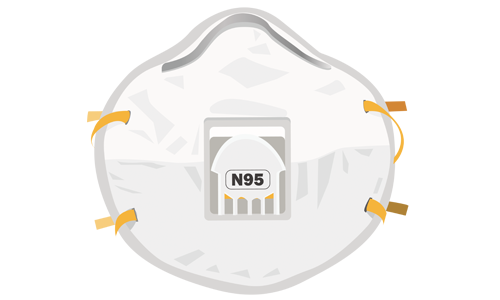

So it’s been for the entire promotional products industry. Once the coronavirus took hold back in March, suppliers and distributors had to become PPE experts virtually overnight.

Beyond educating themselves on a completely new product category, industry companies had to navigate rapidly shifting recommendations from the federal government, work around an overloaded supply chain and avoid price gougers and potentially unscrupulous fly-by-night vendors.

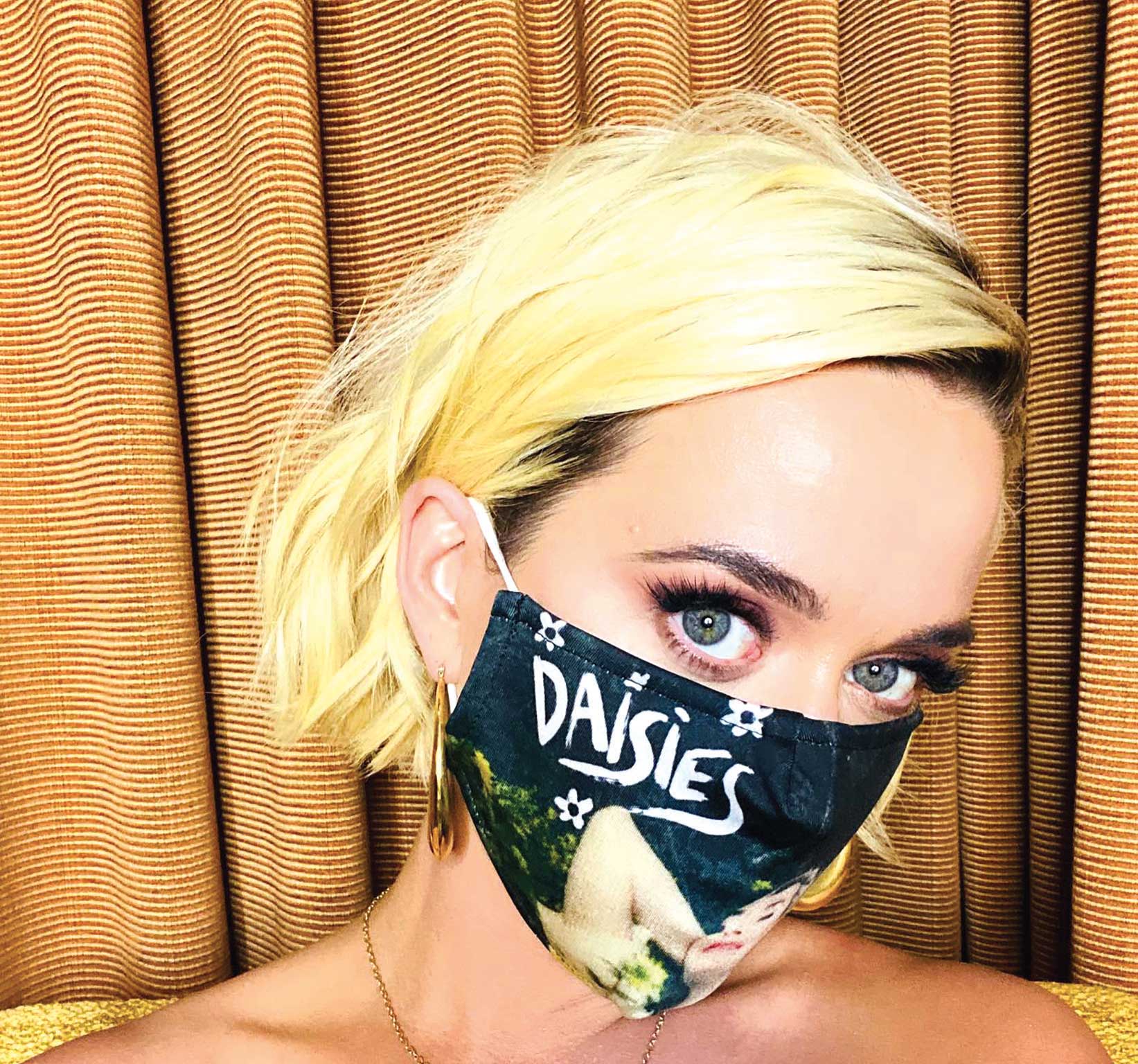

Singer Katy Perry used a sublimated mask from FPS Apparel (asi/53475) to promote her digital album Daisies, which was released in August

Along the way, nonmedical cloth masks have evolved from purely utilitarian, makeshift devices into sophisticated, feature-rich accessories – often with a fashion-forward flair. It was like watching a time-lapse video of the way product lines are typically developed for the industry.

“The normal development cycle for a product might take a year,” says Michael Johnson, director of marketing for Hanes Activewear (asi/59528). “This was a matter of weeks or months to get things ready for market.”

Early in the pandemic, Hanes and several other apparel makers in the industry – including Top 40 supplier SanMar (asi/84863) – were tapped by the federal government to produce cloth masks on a large scale for healthcare professionals to make up for a critical national shortage. Working closely with the U.S. Department of Health and Human Services, Hanes came up with a design for three-ply cotton face masks. In the span of a week, the supplier was able to finalize its designs, get approval by the Food and Drug Administration, then convert its factories from T-shirts, fleeces and other basics to ramp up mask production. SanMar and other members of the cooperative consortium of apparel manufacturers also transformed their operations into mask-making machines. “The government really kickstarted us into working quickly with masks,” says Renton Leversedge, chief customer officer at SanMar.

4,235

Number of impressions per promo mask over its anticipated lifetime

2020 ASI Global Ad Impressions Study

Over the course of three months, Hanes made more than 450 million face coverings for the government. SanMar made more than 100 million.

That trial-by-fire helped the apparel manufacturers when they shifted into making nonmedical cloth masks for promo distributors and decorators. “Because we had these government masks, we immediately started doing consumer insights with wear tests,” Johnson says. “It’s a much more complex engineering feat to work around the face and provide adherence than one would have thought. But we were able to understand really quickly that for a person to wear a mask regularly, it’s got to be comfortable, breathable and provide facial adherence. The actual performance aspects are more important than the aesthetic.”

Speed was of the essence in bringing masks to market, partly because of the public health component, but also for economic reasons. “Our industry dropped like a rock very quickly,” Leversedge says. “There was a big rush to support our customers to have something to sell because T-shirts weren’t selling. Plus we had 7,000 sewers in Honduras who needed those jobs.”

“The mask development process was so much smoother because we couldn’t think as much. We just needed to act fast.” Kevin Johnstone, FPS Apparel

In many ways, the design and prototyping process was actually improved by the urgency of the situation, says Kevin Johnstone, director of sales and marketing at FPS Apparel (asi/53475). “We were forced to act fast,” he says. “In our normal custom apparel product development, we get distracted, push things to the side to address other more immediate concerns or come up with lots of good ideas without acting on them. The mask development process was so much smoother because we couldn’t think as much, we just needed to act fast.”

The Chester, NY-based supplier designed its masks in two days in March, after New York Gov. Andrew Cuomo ordered nonessential businesses in the state to close and put out a call for manufacturers to help develop and source desperately needed PPE. “Over the weekend, we tested a few mask styles, sourced materials and figured out all that goes into manufacturing cloth masks,” Johnstone says.

Mask production became so ubiquitous that even smaller distributors were trying their hand at it. Ruth Cyphers, president of AdMfg Inc. (asi/105165) in Fairmont, MN, likes to sew in her spare time and was approached by a friend who needed to wear a mask all day at work but couldn’t stand the feeling of the elastic pulling on his ears, nor did he want to have to tie a mask around the back of his head. Cyphers spent a weekend sewing up various prototypes, testing them on her friend and making adjustments until she hit on the winning design: a reversible mask that attaches around the neck, using a Velcro strap, rather than over the ears or around the head. “The trick was to get it so it holds on the nose comfortably, but you can put it around your neck as tight or as loose as you want it,” Cyphers says.

57%

of conumers would be more likely to do business with the advertiser who gave them a promo mask

2020 ASI Global Ad Impressions Study

Her friend was satisfied with the product, which Cyphers dubbed the ComfyMask, and soon other people started knocking on her door to express interest in getting their own handmade mask. Cyphers decided to start selling the product through AdMfg’s sister company, SewMfg. Says Cyphers, “We’re not competing with anyone who wants to sell thousands of them – we’re just trying to do our thing to help everyone be more comfortable.”

When it comes to masks, it’s all about striking a balance between comfort and effectiveness. A thicker mask with multiple layers of tightly woven cotton would be more effective at blocking respiratory droplets, but more difficult to breathe through. A comfier mask made from a looser weave or fewer layers might offer better breathability, but blocks fewer droplets.

Hanes used its intimate knowledge of designing “innerwear” to help ensure the masks it released would be comfortable while still doing the job they’re meant to do. “For many of Hanes’ categories, comfort is job one,” Johnson says. “So, we had plenty of experience working with fabrics and sewing techniques that were essential to providing comfort.”

Kotis Design was lucky enough to have a long-standing relationship with an athleisure apparel factory that had already been making masks for a decade, Thomassen says. “A lot of the masks we saw initially were pretty flat,” he adds. “Ours has a shirring on the edge so when you wear it, it cups your face better and flexes to more face shapes.”

Of course, comfort can be subjective. “Some people want a nose bridge, some people don’t. Some want the elastics an inch off the ear, some want them around the ear,” says Jason Emery, vice president of Toddy Gear (asi/91411). In terms of available variations, “It’s almost like the new T-shirt.”

Going hand-in-hand with comfort is the issue of fit. Heads come in all different shapes and sizes, and unlike with T-shirts, the idea of small, medium and large is still new territory when it comes to face masks. “There’s no standard for how you design a fit,” Hanes’ Johnson says. “It took a lot of experimentation to determine the optimal size.”

56%

Percentage of women who have a more favorable opinion of an advertiser who gave them a promo mask – a higher amount than men (45%)

2020 ASI Global Ad Impressions Study

For the promo market, where distributors are filling larger orders, it’s crucial to make the fit as universal as possible – which is where adjustability comes in. Many suppliers offer ear loops with adjustable sliders, for example, so one mask style fits more heads and distributors have fewer complexities and inventory snags to contend with.

Another challenge for suppliers was creating masks that were decorator-friendly. Just as people are less willing to wear a mask that’s needlessly uncomfortable, few people are thrilled with the idea of covering half their face with something that looks bland, boring and clinical. “I think that our industry can play a massive role in people wearing masks,” Leversedge says. “A simple white mask is not a fashion statement.

“I know if I give my kid a white mask to wear versus a Star Wars mask, he’s going to choose the Darth Vader mask.”

39%

percentage of consumers who own a promo mask

2020 ASI Global Ad Impressions Study

A lot of product testing that suppliers did during the development stage involved printability – sending out samples to printers and equipment manufacturers to figure out which mask designs would be most conducive to adding screen prints, dye sublimation, heat transfers or other embellishment. For example, pleated masks or those with center seams are problematic when it comes to adding a logo or other design. Jonathan Aguirre, general manager of Zuni Sportswear (asi/99559) in California, initially thought of modeling his company’s masks off a template provided early on by Los Angeles officials, but was glad when he ultimately decided against it. “I wasn’t thinking about the printer-friendly aspect,” he says. “The template had a bunch of folded ridges. Our customers weren’t going to be able to use it.”

Instead, Zuni focused on providing a flat area with a big enough surface to hold a logo. The masks are made from the same fabric as its T-shirts, so “customers already familiar with printing on our T-shirts can easily know they can trust it,” Aguirre says.

“I think that our industry can play a massive role in people wearing masks. A simple white mask is not a fashion statement.” Renton Leversedge, SanMar

Hanes created its Pocket Mask specifically for the print market. The two-ply mask has an inner pocket that fits on a sleeve/pocket platen to accommodate logos, and it’s available in both cotton and polyester versions, so it works for either screen printing, direct-to-garment printing or dye sublimation.

For bold, all-over prints on a mask, sublimation on a polyester outer layer works best. If you’re screen printing, it’s generally not recommended to put a logo across the mouth because the ink can block airflow. However, many decorators are putting logos on the cheek of masks. “It’s important to consider how a mask looks when stretched on the face as opposed to how it looks out of the package,” Johnson says. Just as polos have the classic left chest logo, printed masks are developing placement standards. Designs placed on the cheek are at an ideal spot for visibility, without being too in-your-face. Plus, if the logo is situated higher up on the mask, it’s less likely to warp when the mask is worn.

Now that the industry has upgraded its mask offerings and ironed out the supply issues that plagued the early days of the pandemic, the biggest question remaining is just how long the need for masks will continue?

“We talk about this on a weekly basis,” says Cheryl Aguirre, vice president of Zuni. “We’re being cautiously optimistic that it’s not going to last forever, so we’re keeping our inventory at a manageable level.”

1/10 of a cent

CPI of an imprinted mask that costs $5

2020 ASI Global Ad Impressions Study

Even after the coronavirus threat is gone and the need for masks dwindles, industry experts say the promo industry’s foray into PPE will have made a lasting impact.

“We hope that we’re out of the mask business as soon as possible,” Leversedge says. “We’d rather sell T-shirts and sweatshirts and polos, but we think this PPE category is here to stay for us.” SanMar has been investing in sewing plants to make gowns and scrubs on a more permanent basis.

In the meantime, while masks are still a necessity, it’s important to offer clients high-quality options. “In the early days, it was all about, ‘Can I get masks?’ Now, it’s about, ‘How do I get good masks? Who has them available?’” Johnson says. “You don’t want to put your name and logo on an inferior product. A mask is really reflective of how you care about your customer and staff, probably more so than any other category.”