Product Hub September 30, 2015

Equipment List

Productive Essential for Small Shop

Flash Cure Unit

It’s OK to let your dryer do most of the work, but a flash exposure unit is still an essential part of your arsenal. The Riley Hopkins 18” x 24” flash dryer from Ryonet (asi/528500; circle 116 on Free Info Card) can be easily positioned thanks to its heavy-duty stand and casters. It features tilt-control adjustment knobs and a built-in heating control unit.

Electric Dryer

When space is at a premium in small shops, a compact-but-capable electric dryer is a must. The RileyCure conveyor dryer from Ryonet (asi/528500; circle 116 on Free Info Card) features a four-foot tunnel and 24-inch wide belt to accommodate jobs from multiple presses – up to 220 shirts per hour.

Six-Color Manual Press

For a shop growing into consistent business, look to the RileyROQ from Ryonet (asi/528500; circle 116 on Free Info Card). The six-color, six-station manual press features tool-free adjustments, aluminum pallets and standard micro registration. Available in 6-6, 8-8 and 10-10 configurations.

Make a move

Your dream site has been selected, the layouts have been determined, even the furniture is picked. “Now you have to move there,” says Judy Kellem, founder of FRC. “You have to make sure the phones are working, the equipment is working, everything is laid out, and all the contents have been moved.” There are a thousand little details to be attended to as you move into your new space. You can do it all yourself, or you can make it easy and hire a Facilities Relocation Consultant (FRC). Regardless of the industry, Kellem says, “a move is a move is a move,” with similar needs for any company moving into a new space. Here are three tips from Kellem and her white paper, “10 Steps to a Smoother Move” (available at FRCmove.com):

1. Give plenty of notice to your communications vendor. Make sure that your vendor is working closely with your office manager to identify the equipment needed for the space that you have defined. Your office layout may change during this process. IT and telecommunications needs sometimes dictate where things need to be set up.

2. Check your existing lease to determine “close out” conditions. This is simply the condition in which you are required to leave your current space. It should be clearly spelled out in your lease. If you did not occupy your space too hard, meeting your close-out conditions may involve as little as leaving the space “broom clean.” On the other hand, some leases require that spaces be repainted after you move out.

3. Make arrangements for the new space to be cleaned before you move in. If nothing feels quite as good as moving into a clean workspace, nothing feels quite as depressing as moving into a dirty one. You can make arrangements to have a housekeeping staff clean the space completely before the first day for you, your staff and your customers.

Top-of-the-line machines for a medium-sized shop.

Splurge!

Dual Unit Heat Press

Keep your heat press productivity humming with the Dual Air Fusion heat press from Hotronix (circle 84 on Free Info Card). Press one garment and prepare another at the same time with dual pallets and an upper platen that glides between each station. Touchscreen controls and laser alignment system for each station are the cherries on top.

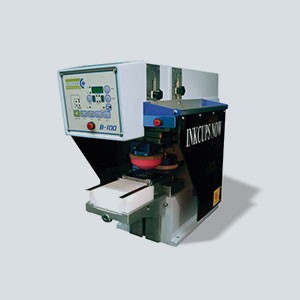

Necktag Pad Printer

Custom private label necktag prints are an enticing option for any client. Shops can certainly use a sleeve pallet and press to print them, but a dedicated option like the tagless system pad printer from Inkcups Now (circle 119 on Free Info Card) offers cost savings and turnkey functionality.

Automatic Press

Versatile automatic presses are still a growing shop’s bread and butter. The ROQ YOU auto from Ryonet (asi/528500; circle 116 on Free Info Card) is available up to 18 colors and 20 pallets, and includes a central control panel with LCD touch screen as well as independent control panel on all print heads.

Splurge!

Screen Printing DTG Add-On

Want to add exciting effects like foil or flock to DTG prints, or simply trying to save on ink costs? The Paradigm II from Kornit Digital (asi/14972; circle 117 on Free Info Card) attaches to any automatic or manual press (even ovals) with no setup.

Splurge!

Industrial Direct-to-Garment Printer

As direct-to-garment technology continues to evolve, a DTG printer is essential for short runs and meeting increased demand for personalized garments. The Avalanche Hexa from Kornit Digital (asi/14972; circle 117 on Free Info Card) offers a high-production solution with advances like increased color range and large print area for XXL and cut piece garments.

Gas Dryer

The venerable Sprint gas dryer series from M&R (circle 81 on Free Info Card) has been upgraded with the Sprint 3000, which offers a color touchscreen control center and high-capacity circulation and exhaust blowers.

Splurge!

Oval Automatic Press

Once a forgotten relic, the oval press has been reinvented to rousing results. Options like the Alpha 8 from M&R (circle 81 on Free Info Card) are modular and expandable – which means they can be configured to fit any production space (unlike its circular brethren). Expandable up to 50 colors and 38 stations ... you know, if you ever need that sort of thing.

8-Head Embroidery Machine

For versatility from small orders to large contract orders, the Tajima 8-Head embroidery machine (TMAR-KC) from Hirsch (circle 118 on Free Info Card) is a strong solution for decorators looking to grow into embroidery quickly. It features innovations like a digitally controlled presser foot that adjusts to the fabric thickness (making it easier to sew on sheer and dense fabrics) and a newly designed middle thread guide that allows for setting tension in half the time as on a conventional thread guide.

Cutting-edge automated machines for a screen room.

LED Exposure Unit

For those without a CTS exposure system, LED units offer lightning-fast exposures with minimal electricity. The Lumitron LED Exposure Unit from Workhorse (circle 120 on Free Info Card) offers 50,000-hour bulb life and a compact, tabletop design.

Computer-to-Screen and Exposure System

Say goodbye to storing and printing films as well as pinholes with the i-Image STE II system from M&R (circle 81 on Free Info Card). This computer-to-screen system automatically prints and exposes screens, and uses a second UV light pass for ultra-fast exposures. Perfect for busy automatic shops, this CTS system can produce at least 150 screens in an eight-hour shift with one printhead.

Splurge!Automatic Screen Coater

If consistency is the name of the game, an automatic screen coater removes the element of unpredictability that comes with coating by hand. The UNI-KOTE automatic screen coating machine from M&R (circle 81 on Free Info Card) offers front and rear coaters to work in tandem or independently, and offers a Job Recall button to save up to five jobs.

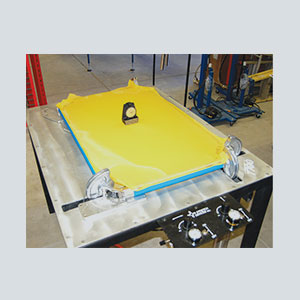

Screen Stretcher

Screen quality is the first (and perhaps most important step) to print quality, which makes a screen stretching table essential. The Newman Roller Masters stretching table from Stretch Devices, Inc. (circle 122 on Free Info Card) offers four-way simultaneous stretching that enables rapid retensioning with less effort and more uniform results.

Splurge!Automatic Screen Washer

Like a car wash for your screens, the Gruning GWash 170XS from Kiwo (circle 121 on Free Info Card) washes, degreases and rinses two screens at once with an in-line chamber. Integrated tanks allow for recycled water and minimal loss of chemicals. Never manually wash out a screen again.

Continue to More Than a Dream Go Back to Small Shop

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.