Product Hub January 21, 2015

Thrift Shops

Penny-pinching printers can save tens of thousands of dollars by purchasing used equipment. They just have to make sure the deal is as good as it seems.

Penny-pinching printers can save tens of thousands of dollars by purchasing used equipment. They just have to make sure the deal is as good as it seems.

John Bowes was tired of paying a “middle man” to print his band’s T-shirts. So, while on tour in Northern California eight years ago, Bowes hopped onto Craigslist and found someone selling a used four-color, single-station tabletop manual press. “It was kind of like a crapshoot,” he says. “Because I was so green to printing, I had no idea what I was looking at or what I was looking for.” What he was looking at turned out to be an overpriced, no-name press that couldn’t hold registration. “It was a piece of junk,” Bowes says. “I definitely did not get the better end of that deal.”

Bowes learned the hard way the risks involved in purchasing used equipment, especially for rookie printers. He eventually scrapped the clunker press that had launched his business, but that early mistake didn’t discourage the owner of Hatfield, PA-based Cold Cuts (asi/528781) from buying more used equipment – including an automatic press and a refurbished exposure unit – to power his successful online band merchandise store. “Purchasing used equipment is great,” he says. “You get what you need for a fraction of the price. You just need to be careful.”

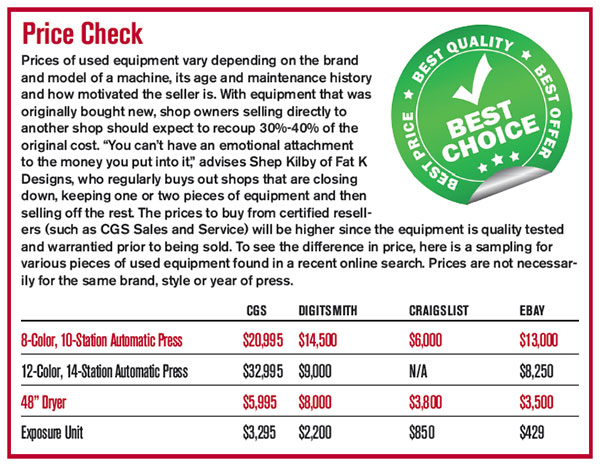

Caution is the watchword in the thriving used screen-printing market, but for decorators who do their research and aren’t afraid to get their hands dirty, the savings can be significant: usually around 50% to 60% lower than the cost of brand-new equipment. “The monetary savings lets you populate your shop with equipment that you probably couldn’t even afford the lease payments on,” says Shep Kilby, owner of Fat K Designs in Bridgeton, NJ.

By going the used route, however, decorators also forgo some of the peace of mind built into the cost of new equipment, such as manufacturer warranties, training and technical support. “Though you spend less money up front, you’re going to spend a lot more money in overhead and labor,” says Ryan Moor, CEO and founder of equipment supplier Ryonet (asi/528500). “When you buy a piece of equipment from a manufacturer and it breaks, they’ll repair it, whereas if you buy used and it breaks, it’s all on you.”

Many screen printers are willing to take that risk. According to survey data collected in the 2014 Wearables Sales Forecast, 70% of decorators have at least one secondhand press in their shop. David McLain, a Novato, CA-based broker who specializes in used M&R equipment, says the demand for preowned automatics outstrips supply. The owner of Screenprinting Products estimates that he has about 150 printers ready to buy presses, but is only able to accommodate about 40 transactions a year. “We’re constantly doing deals,” McLain says.

Do Your Homework

There are many ways to find used equipment, ranging from word of mouth to the power of Internet searches. On the riskier end are sites like eBay or Craigslist. “A lot of people try to buy their used equipment off of Craigslist,” says Kilby. “While the prices might be cheap, you’re generally getting very old or entry-level equipment. You’re doing yourself a disservice. The people on Craigslist are all selling stuff off because they have no clue what they’re doing.”

Industry-specific avenues for purchasing used equipment include online message boards like www.t-shirtforums.com, www.digitsmith.com and forums set up by equipment manufacturers like M&R (forums.mrprint.com). Financing company Beacon Funding has its own sister site (www.equip-used.com) to resell repossessed equipment. Brokers and refurbishing shops are another route for secondhand shoppers.

The key in any of those methods, however, is doing some research and having a plan: Find out which brands are known for reliability, get a sense of where the equipment is in its life cycle, run price comparisons and evaluate how a particular machine will fit into your business model. Just as you wouldn’t buy a used car without first taking a test drive, you shouldn’t buy a piece of equipment before first seeing it in action. At the very least, examine pictures and perhaps YouTube videos of the items you’re considering buying. Bowes says he likes to hire a machine technician to inspect used equipment “to make sure I know what I’m getting into” before making a purchase.

You should also have an idea of the features that are necessary for your business and which you are willing to sacrifice. Sometimes the bells and whistles are just that, says Tony Pernicello, owner of CGS Sales and Service in Pennsauken, NJ, which deals in used equipment. An automatic press that’s a decade newer than the one you’re looking at will likely have some changes, but “they might not necessarily be advancements for the printing end,” he adds.

That’s how Tony Esteves, president of Tiny Fish Printing in Rochester, NY, feels. “We’re not caught up in the glitz and glam of the fancy buttons and LCD screens,” he says. “We’re a bit more pragmatic.” A proponent of electric presses, Esteves says that as long as the equipment has a good motor and a respected brand name, “you’re already ahead of the game.”

Another aspect to consider is whether the used equipment you’re assessing has an upgrade path through the manufacturer, says Kilby. For example, certain manufacturers allow owners to swap out parts to transform, say, a six-color press to an eight-color model. Kilby once purchased a used four-color Vastex press for next to nothing, then sold some of the parts, and used the proceeds to have the manufacturer upgrade it to an eight-color press. “At the end of that buy, I had a free $8,500 press sitting on the floor,” he says. “It’s on the books as zero dollars.”

Seeking Guarantees

Seeking Guarantees

Though you’ll never get the kind of warranties offered by manufacturers for new equipment, several used dealers offer short-term warranties on their machines, anywhere from 60 to 120 days, and other perks to allay buyers’ worries. McLain of Screenprinting Products, for example, has a nationwide network of machine techs that he deploys to evaluate any press before he purchases it. Equipment is thoroughly cleaned before shipping, and McLain insists that one of his own technicians install the used press in its new home to ensure it’s done properly. He pays for any replacement parts required during the installation. “We take a lot of risk out of people from buying used,” he says. “There are a lot of used equipment brokers that have a really bad name. I pride myself in having one of the better names.”

Pernicello uses only original equipment manufacturer (OEM) parts on the automatic presses he refurbishes. “We say it’s refurbished, but it’s a full-on rebuild, soup to nuts, from mechanical and electrical to cosmetic,” Pernicello says. “It’s not as fancy or as glamorous as restoring an old Corvette, but it still looks good and shiny when we’re done with it.” In addition to offering a 90- to 120-day parts warranty, CGS Sales and Service puts each machine through a barrage of simulated runs to ensure everything is working smoothly. Pernicello also offers free tech support and often finds himself answering customer emails after hours or on weekends. “My cellphone is always on,” he says. “Most brokers are not going to offer that.”

Still, many frequent purchasers of used equipment say they’re not too worried that their presses aren’t under warranty because they feel comfortable around machinery and aren’t afraid to make their own fixes. “If you are actually servicing and taking care of the equipment, there are really no issues,” Bowes says. “If you’re mechanical and know how to turn a wrench, you can probably repair anything pretty easily.”

Bowes and others recommend ordering spare parts for items that are prone to wear, particularly belts, hoses and fittings. That way, you’ll have them on-hand and be able to make a quick fix, without a lot of machine downtime cutting into your bottom line. If there’s a press with 10 identical parts and one breaks, it’s often a good idea to replace all 10 at the same time, Kilby says. “You can bet the others will go soon,” he says. “If you don’t treat the used equipment in that manner, it will be a constant source of aggravation.”

The life expectancy on any machine, new or used, really depends on how well a customer takes care of it, Pernicello says. He recently spent seven weeks rebuilding a 2001 14-color automatic press before selling it to a customer in Maryland. “Under normal maintenance, it should last easily another 10 years and do five million prints,” he adds.

As Esteves notes, many of the printers he admires most are using presses that are a decade old. “If it’s good enough for them to create award-winning prints, it’s good enough for us,” he says.

Theresa Hegel is a senior staff writer for Wearables. Contact her at thegel@asicentral.com and follow her on Twitter at @TheresaHegel.

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.

Sponsored Content

5 Terms That Will Increase Your Performance Workwear Sales

When you present workwear, buyers want to hear how the apparel will perform on the...

Your Direct-to-Garment Printing Solution

Meet the RICOH Ri 3000 and Ri 6000, a brand-new line of printers that combine the...

SPONSORED BY:

AnaJet

Don’t Settle. Buy Better. Buy DRI DUCK.

Take an inside look at the details that define the quality, comfort and durability...

SPONSORED BY:

Dri Duck

Qmulative Discusses Fashion, Business and Next Level Apparel

New Deck eleven six two zero two five six