Product Hub March 03, 2015

Stitches Top Shops

Meet the decorators who stood out this year, setting the industry standard for quality and service. By Theresa Hegel and Crissa DeBree

To identify Top Shop candidates, Stitches sent an open invitation to apparel-decorating companies, including apparel suppliers, and many interested shops responded. Stitches staff evaluated shops based on a range of relevant criteria. While total revenue and volume of pieces embellished annually were important factors, they were far from the sole determinants. Shops were also selected based on their innovative business/decoration practices, customer service abilities as determined by feedback from clients, industry staying power, growth trajectories, adeptness in different decorating mediums and more. Critically, decorators were also evaluated on embellished samples they sent Stitches; these works demonstrated the breadth of services and level of expertise of each shop.

This year's Top Shops have something in common, besides a strong work ethic and superior technical skills. They understand that they're selling a service, not just a product, and go above and beyond to ensure their customers are always satisfied. Whether that involves fulfilling last-minute rush orders without breaking a sweat or coming up with innovative embellishment techniques to tackle clients' most difficult design problems, these apparel decorators are up to the challenge.

This is the second year Stitches has scoured the country to highlight the best and the brightest in custom embroidery and screen-printing decoration, and the competition was as fierce as in 2014. We asked shops to submit work samples and in-depth information about their operations. After a thorough analysis, our editorial team selected four standouts: a direct-seller with a knack for complicated design, a high-volume contract scree-printing shop and two suppliers with thriving decoration arms.

Each shop featured this year demonstrates an aptitude for innovation and an unflagging entrepreneurial spirit. Turn the page to gain inspiration from the work these Top Shops are doing. We also checked back in with some Top Shops veterans, asking 2014 honorees to share their latest triumphs, best advice and trend forecasts. Check out their responses on page 48.

The Speedy Deliverers

The growth of St. Louis Print Co. (asi/700623) has been fueled by a desire to keep up with customer demand for a quick turnaround time.

Terry Keeven was 16 years old when he landed his first job in a screen-printing shop, offloading an automatic press. By 19, he was a production manager. By 21, he was general manager of a small shop that more than quadrupled in size under his leadership.

A decade later, he's his own boss. His company, St. Louis Print Co. (asi/700623), has seen tremendous growth since it opened in 2007. Today, it prints more than 1.7 million pieces for 475 clients. The shop recently completed its largest and most expensive expansion yet, adding a new manual press and a 12-color automatic that can handle larger and more detailed imprints.

The expansion, Keeven says, is driven by customer demand for high-quality product in a short amount of time, and will allow St. Louis, which decorates apparel for the promotional products industry, to pursue new markets and continue its rapid growth.

Providing customers with what they want quickly has been the focus of St. Louis Print Co. since the beginning, when Keeven financed the fledgling shop with a home equity loan. He started off with one automatic and one manual press, and four distributors who were willing to send him all their work.

"I realized from day one that if I don't make the customers happy, they can go anywhere else," Keeven says. "Here in St. Louis, the market is super saturated with screen printers. They have plenty to choose from. I knew we had to be the best in customer service. I always ask, 'How are we treating you?' When customers bring up the same thing over and over, we fix it."

One of the biggest topics, Keeven says, has been turn time. Customers not only want quality items, they want them quickly. "It seems like everybody wants their stuff in five days or less," he adds. "We've been able to do it. Every time we go beyond five days, we start talking about what we have to do."

After turnaround time reached 10 days last year, Keeven began thinking about expanding. While typically St. Louis Print Co. just replaced outdated equipment, this year it decided to purchase two additional presses to handle the demand. One of the new presses also expands printing capabilities to 19" by 19" (up from 12" by 18" on older presses), which Keeven believes will attract new customers.

"It works well for us," Keeven says. "We're a small business, but we're a pretty large business for our industry. You don't see too many print shops with six autos and six manuals and 40-some employees."

Customer service and attention to detail is what has kept customer FiP creative coming back for more. The firm, a Stevens, PA-based distributor of apparel and promotional products, has contracted with St. Louis since 2012 for its corporate and school/team apparel needs.

"Terry and his employees go above and beyond with their attention to detail and communication," says Kristi Fisher, office manager. "They always deliver a quality product that you can be proud to give to your customers. They make sure the job is done right, on time and communicate throughout. Their customer service is unbeatable. We weighed freight cost for using them, as we're in Pennsylvania and continue to see the expense well worth it for the quality and customer care we receive."

Over the past seven years, St. Louis Print Co. has grown from a three-person operation to one with more than 40 employees. Keeven's brother Sean oversees production. Two of his employees are men who taught him the business when he first started. Half of his employees are childhood friends. His former bosses are now among his clients.

"Because of our background and my relationship with all our employees, it still feels like a mom-and-pop shop," he says. "I can come out, talk to the guys. I know these guys. I know their families. They know me, my wife and my children. We hang out on the weekends. These are my printers and my dryer catchers. It's very unique."

Employees at St. Louis Print Co. get things done quickly and with the highest quality. But they still like to have fun, Keeven says. Guitars and gold records hang on the shop's walls. Offices are painted bright green and blue.

"Any small business is somewhat of a reflection of the owner and an extension of the owner," Keeven says. "Because I'm young – I'm 32 years old – and I listen to country music and rock music, and I'm covered with tattoos, and I have earrings – since that's what I like, I tend to hire employees who are like-minded. And I try to make our atmosphere like that."

But when dealing with customers, Keeven says, it's all about professionalism. "We're not catering to the end-users who want these cool shirts," he says. "We cater to the promotional products market. We're dealing with a lot of professionals who might not necessarily dig that vibe. We do walk a fine line. We're young, we're tattooed, we listen to rock music. But you'd never know that if you just called us. We're very professional. We just have a little bit of a rock 'n' roll vibe." – CD

The Problem Solvers

Black Duck Embroidery and Screen Printing (asi/700415) has been flying high for 25 years by specializing in complicated, high-end decorations.

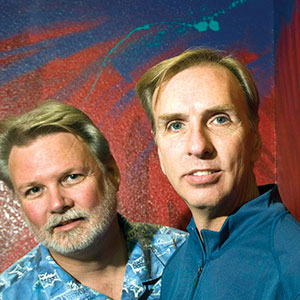

Brothers Doug and Dana Bird founded Black Duck Embroidery and Screen Printing (asi/700415) to do more than just "put ink on a shirt." Over 25 years, they've earned a reputation for their ability to tackle complicated designs and provide high-quality product to their customers.

Their success, they say, stems from attention to detail, longevity and the ability to take on even the most difficult projects. "We spend time with each of our customers, trying to determine who the end-wearer is going to be, so we can provide them not only with what they ask for, but what they actually need," says Dana Bird. "They don't always know what options there are. Just from our experience, we know certain products are good for certain industries or certain types of users. We can help them better identify what they really need, even if they don't know they need to ask for that."

Crane Services Inc. has relied on Black Duck for more than a decade to reproduce designs as complicated as the heavy equipment Crane Services sells. "For them to accurately represent that through stitching is quite difficult," says Chris Martin, marketing coordinator. "But Black Duck and their team are able to do that. They're able to replicate our designs into screen printing, embroidery or a little bit of both. We hold them to extremely high standards. When we give this stuff to customers and our employees, there's an implied quality and value there. If you give your employee or customer something that isn't impressive or lacks in quality, that implies your company itself lacks quality and value. It's an image everybody sees on job sites, on external marketing. We have to have it looking top-notch."

Both Doug and Dana Bird left corporate careers – Doug in advertising and Dana in banking – to found Black Duck in 1989. Doug was tired of not getting the quality products he needed in the time frame he was promised. "They were just putting ink on a shirt," Dana says. "They weren't worried that what they produced was solving the needs of the customer. They never asked who the end-user was going to be."

The brothers bought a four-color, four-station manual screen-printing press and started their business in a 400-square-foot room. They chose the moniker "Black Duck" as a nod to their avian last name and a desire to stand out among competitors, Doug says.

"We wanted a name that was different from everybody else," he says. "If you went to the Yellow Pages and looked up screen printers or embroiderers, there's 15 different companies that start with 'Graphic' or end with 'Graphic.' We wanted something that once people heard it, they would remember it."

At Black Duck, every order gets personal attention and care, no matter the size. The company does everything from produce T-shirts for the annual Mudd Volleyball tournament benefitting a local children's hospital – the Birds serve as tournament directors – to props and gifts for the many TV and film production crews that shoot in and around Albuquerque, NM, most notably the hit TV show Breaking Bad.

"We have several clients who call us during the day and will expect to pick [the order] up by the end of the day," Dana says. "Working for some of the movie projects in particular, their timeline demands are, 'We're shooting a scene tomorrow, and I need this.' We're one of the companies they know can handle that if they need it."

The shop's 20 full-time employees have an average tenure of nine years with Black Duck, which the Birds feel is recognition of the culture they've worked hard to establish. It's a family business that demands excellence from everyone.

"We tend to have the cream of the crop in New Mexico," Doug says. "The very best printers, the very best embroiderers, the very best digitizers, the very best artists. They all work here. They're similar people to Dana and I. Our goal is quality and making sure the customer is satisfied. The employees we have aren't just people who want to put ink on a shirt. They want to make sure that whatever process we're doing is actually the very best process for that customer and for that situation. Good enough is never good enough around here."

At Black Duck, the goal is to provide a seamless process, from start to finish, the Birds say. "One of the comments I hear regularly after someone comes in and places an order is, 'That was so easy,' " Dana says. "Their expectation was that ordering shirts for their company is a tough process. They don't see all the inner workings, but they know if they come in and ask for something, they get what they wanted, and it was right." – Crissa DeBree

The People Pleasers

It's one big happy family at MV Sport/Weatherproof (asi/68318), known for innovative custom designs, stellar customer service and a commitment to environmental sustainability.

The sweatshirts were late – tucked away somewhere in a cavernous Minneapolis UPS distribution center after a heavy snowstorm had delayed shipment. But Matt Leighton of Preferred Design (asi/298340) in St. Paul, MN, didn't panic, even though the shirts were needed for an event later that same day. Instead, he picked up the phone and called MV Sport/Weatherproof (asi/68318). With the help of his "go-to supplier" and UPS, Leighton was able to locate his order inside the packed warehouse, toss the garments in his truck and deliver them on time without a glitch.

That's why Leighton has stuck with MV Sport for more than a dozen years. Employees of the apparel supplier and custom decorator care about Leighton and do whatever it takes to ensure his success, he says. Even in the aftermath of the devastating Hurricane Sandy three years ago, when much of Long Island was blanketed in power outages, the Bay Shore, NY-based company was able to ship Leighton's custom orders to Minnesota on time. "That's huge," Leighton says. "In our industry, a lot of suppliers say they have service, but then they don't pull through, and you get product three days after an event when it's doing nobody any good. … [MV Sport] has always backed my deadlines and supported them."

Leighton's story is not unusual. Quick turnaround and top-notch customer service are hallmarks of the family-owned and operated MV Sport, helping it nab a spot on this year's Top Shops list. "We'll bend over backward for our customers who need things right away, even if it requires us sometimes to leapfrog orders in the system," says Dov Singer, vice president and general manager of operations at MV Sport. "We're not shy about any capacity to make sure that we satisfy our customer base. … Our employees are so dedicated. They work really hard, and they don't take a break. They'll go to the end of the earth for everybody."

The reason behind employees' dedication is simple, says Susan Farino, account manager at MV Sport: The hands-on owners treat workers like family, promoting from within whenever possible and supporting them, both financially and emotionally, if they fall ill, lose a spouse or undergo some other personal trial. "It's not like a big corporate place where you feel like a number. [The owners] do take such pride in their product and people. It kind of trickles down to us as well," adds Farino, who started out in general customer service with the company in the 1990s, before moving up the ranks to her current position.

MV Sport/Weatherproof's parent company was launched in 1948, though the apparel supplier didn't enter the custom decorating game until the 1970s. "We always joke that we got 12 to 15 units out of the screen-printing shop that first day," says Josh Peyser, company president and grandson of company founder, the late David Peyser. "Now we do tens of thousands of imprints a day." Known for its innovative and creative decoration solutions, the $50 million company fulfills more than 100,000 orders each year, whether using embroidery, screen-printing, laser-etching, heat-transfer, sublimation or multimedia techniques.

What sets MV Sport apart is its strong positioning in the retail market and a holistic approach to garment decoration, Peyser says. "We really try to integrate our graphic ideas with the styling so that it really is a cohesive set," he adds. "Our apparel merchandisers sit next to our creative graphic artists with the same goal. You speak to some of the great screen printers out there, and the shirt is a canvas. They do amazing work, but it's on a basic T-shirt. We see things as a little more integrated than that." That means traditional garments are married to more traditional embellishments, whereas fashion styles often get bolder designs, perhaps employing multimedia techniques.

Peyser points to MV Sport's new "super hot" item: a lightweight, packable down jacket that folds up into a little bag. The style was trending on the retail side, and the company knew it would be a hit in the ad specialties world as well. "This is a style that has real staying power, and I think we were on top of the trend before other brands," he adds. Because MV decorates its own garments, the company was able to run ample testing to ensure that the jacket would "embroider beautifully with no special handling," Peyser says. "You don't want to find out it can't be decorated when there's thousands of units sitting in a warehouse."

The other big part of MV Sport's DNA is its commitment to sustainability. In 2012, the company flipped the switch on a massive solar power installation that provides more than 90% of its electricity needs, reducing carbon dioxide emissions by 2 million pounds annually. Other eco-friendly initiatives include a state-of-the-art screen-printing reclamation system that minimizes water usage, motion-detected high-efficiency lighting throughout the warehouse and a company-wide paper, aluminum and plastic bottle recycling effort. "We all live and work here; it's our community," Peyser says. "It just seemed like the right thing to do." – Theresa Hegel

The Quality Controllers

At Cutter & Buck, which has been manufacturing and decorating premium apparel for more than two decades, everyone is responsible for ensuring the highest quality.

Cutter & Buck (asi/47965) wants its customers to feel as comfortable in the boardroom as they are on the golf course, all without having to change their clothes. As a result, their products must be high-quality while embracing the sensibility and the versatility of the Pacific Northwest, which the company calls home.

"From top to bottom as a company, everyone at Cutter & Buck takes pride in the finished product and takes pride in the brand. That's a big part of our success."

Ty Cannon, Cutter & Buck (asi/47965)

"We want our clothing to take you from a business meeting to your bike ride home, to your boat ride, or up into the mountains to go skiing," says Ty Cannon, national business development manager. "To do that, we had to make apparel that was seamless. We embraced our heritage and tied that into the products we design. It's really about making a product that is very, very useful for several different types of activities, and for a large group of people."

It's that quest for quality that led the company to begin offering in-house embroidery nearly 20 years ago. Last year, the company affixed more than 2.5 million logos – and that number is expected to grow this year in both embroidering and heat transfers, which the company began offering a few years ago.

"That tradition of wanting to control the quality, which prompted buying the machines and bringing production in-house, is one of the primary elements" to Cutter & Buck's success, says Diane Spaur, enhancement operations manager at the firm's distribution center in Renton, WA, located about 15 miles from the company's Seattle headquarters.

The average length of service for embroidery employees is 10 years, and Cutter & Buck prides itself in the knowledge of its team. Each person is tasked with quality control.

"One of the things we think makes us different is, we don't have roving inspectors," Spaur says. "Every single person who touches the customer's order is responsible for the quality of what, as a team, we're going to send to the customer. That makes for great quality and everybody feels like they're a part of something. That complements the Northwest sensibility as well. It's not the kind of place where there's a hierarchy. We're definitely a part of the team."

Cutter & Buck's "embroidery development" consists of two full-time digitizers and 10 customer service people dedicated just to embroidery operations.

"If you want to talk product, we've got customer service for that," says Scott Sumpter, director of distribution, enhancement and logistics. "But if you want to talk decoration, we have people dedicated to help you choose the thread colors that are going to work great with every product we carry. Or help you design something that's a little bit different, a little bit special. That sets us apart as well."

Ten years ago, Cutter & Buck rolled out an incentive program in which employees can earn up to $3 an hour above their base salary if they meet certain productivity and quality goals. Rewards are tallied every two weeks.

"It not only keeps everyone focused at every level on the things that are important, keeping our costs down and keeping our quality and our throughput high, but it really keeps employees engaged," Sumpter said. "When you have been doing the job for 14, 15 years, it can still be fun and challenging and engaging."

Sunrise Identity (asi/339206), a distributor in Bellevue, WA, has relied on Cutter & Buck for more than 15 years to deliver high-quality uniform apparel. "What we deliver to our clients is a direct reflection of our company," says Brian Towne, account manager. "When we want to deliver something to our client, and there are some complex details we want to make sure we hit, going with a company like Cutter & Buck, we know that presentation to the client is going to be above standard, and meets what we're trying to get across to our clients."

Adam Parker, co-owner of Georgia-based product distributor Next Play Promotions, said Cutter & Buck has stepped up on more than one occasion, leading to increased business for both companies. "No one likes those last-minute rush orders, but we all get them, and Cutter & Buck has pulled off more than one miracle for us this year," Parker says. "They provided one of our clients with all their apparel for a multi-day trade show. Two days before the event, the customer was still adding additional pieces to the order as they added last-minute attendees. Cutter & Buck produced the items for us in a day and overnight shipped to multiple locations so that all attendees could arrive to the event with their apparel ready to go."

The recent introduction of heat transfer services is further propelling growth at Cutter & Buck, and the company is adding a third shift to its production this year to accommodate demand.

"From top to bottom as a company, everyone at Cutter & Buck takes pride in the finished product and takes pride in the brand," Cannon says. "That's a big part of our success. But as far as finding new customers goes, a big part of that is the consistency and quality that we've shown through the years. We were really the first brand name to break into the corporate industry. We were a little bit of a trailblazer in that sense." – CD

Product Hub

Find the latest in quality products, must-know trends and fresh ideas for upcoming end-buyer campaigns.