Awards July 28, 2016

Fastest-Growing Supplier, 2016 - OrigAudio

One-piece orders and high-end packaging? Sweet music to these audio innovators.

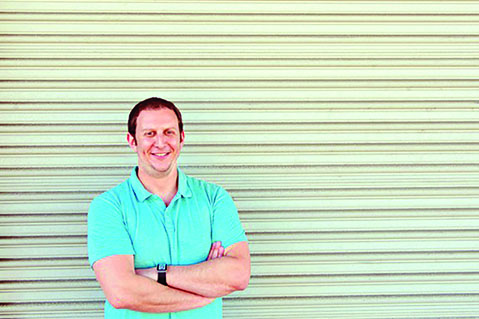

Jason Lucash casts himself as a rebel in the staid promotional products marketplace with a goal to “fight the dark side.” Nevermind the potential hyperbole. Lucash, cofounder of OrigAudio (asi/75254), started the Huntington Beach, CA-based supplier seven years ago with the intent of turning the “very old-school” industry on its head – or at least introducing products that would blow the minds of competitors and end-users alike.

>> Chart: Top 10 largest growers, as measured by sales increases between 2013 and 2015

With growth as high as 600% the last three years, a successful stint on ABC’s Shark Tank in which they received a $150,000 investment and a spot on Time magazine’s 2009 list of the 50 best inventions, they may be doing just that. “We’re busting at the seams,” says Lucash, whose company is expanding at such a quick clip that they’ve had to move offices three times in three years just to accommodate increasing staff and production capabilities. “It frustrates me because it’s hard to handle. We’re figuring out how to stay ahead of the game.”

It’s a nice problem to have. A decade ago, Lucash and his founding partner, Mike Szymczak, were marketers for Major League Soccer and then Jansport, where they ran college marketing and purchased scads of promotional products. “I bought $3 million to $4 million a year from this industry,” Lucash says about his time at Jansport. The duo saw a market that could benefit from more innovative products; eventually, OrigAudio revamped the process surrounding the products themselves – from the way orders are processed to how they’re packaged and perceived.

For starters, the company’s products are shipped in high-end packaging – an effort to “up ourselves” and set a higher bar for how promotional products are perceived and experienced by customers and end-users, Lucash says. The packaging is also a way to put recipients on notice that they’re receiving more than a run-of-the-mill $2 premium that can be admired and chucked in the back of a drawer.

Like most suppliers, Lucash and Szymczak set out to make products that would be impactful, practical, useful and valued for months (even years) after they were delivered in order to increase their marketing value. Certainly they have been innovative. Take their foldable speakers, which Time dubbed one of the 50 most innovative products of 2009. The speakers are expandable and lay flat to store, making it a perfect travel product. Other products include the “Rock-it 3.0,” a self-adhesive piece of technology that attaches to any object (think of a box, cooler or plastic cup) to turn it into an instant speaker.

The company also created “phone soap,” a plastic case containing a UV light that will sterilize any phone while charging it at the same time – and whose claims were proven on Discovery Channel’s Mythbusters. Lucash admits that he and Szymczak knew “nothing about UV light and bacteria,” but that did little to deter them from developing the wildly popular device, or an additional 24 speaker sets and chargers as well. And that may be their key to success: They aren’t afraid to build everything from scratch, even if it means hiring designers, electrical engineers and other tech specialists rather than “buying the same shelf stuff from people in China,” Lucash says, whose company won three awards in this year’s Counselor Product Design Awards. “That’s why it’s our special sauce.”

It inures the duo from being intimidated or stymied by market parameters or typical product lines, all while charging $20 to $75 for products – a massive price point in the world of ad specialties. “You can’t get our stuff anywhere else,” Lucash says, insisting that exclusivity is the key to the company’s growth. The company’s founders look to trendsetting marketplaces, such as those in Japan and other high-tech markets in Hong Kong and Korea, for their innovations.

OrigAudio also offer customers a level of flexibility in their ordering that few in the industry can match, with no order minimums and a guaranteed 48-hour turnaround. (Of course, there are some exceptions. The 145,000-piece order currently being filled for a national shoe company has been promised with a two-week delivery.)

And unlike the vast majority of suppliers that will welcome larger orders over everything else, Lucash wants it the other way. “I would rather have 1,000 one-piece orders than one 1,000-piece order,” he says.

How does the supplier pull it off? By pooling orders. Though it touts a one-off production model, the reality is that the company prints multiple corporate orders at the same time. So “three State Farm orders, 50 Pepsi ones, 25 Blue Cross/Blue Shield orders” fill their print capacity at once, along with a series of additional “one-piece orders as filler spots,” Lucash says. That way, space isn’t wasted and companies with single product requests can have them filled at a reasonable cost in a timely manner. With many repeat single orders, they can count on always having pieces to fill empty slots during runs. “This morning of all the orders we got, 18 out of 25 are less than five pieces,” Lucash says.

Though Lucash and Szymczak can’t say specifically what their company may look like 10 years down the road, for now their business model is working. And, most importantly, Lucash insists, so is their corporate philosophy: “Our goal is to take over, dominate and fight the dark side,” he says. And who would that be? “The suppliers who do it old-school.”

Email: betsycummings23@gmail.com; Twitter: @asicentral